Maine Surface Finishing

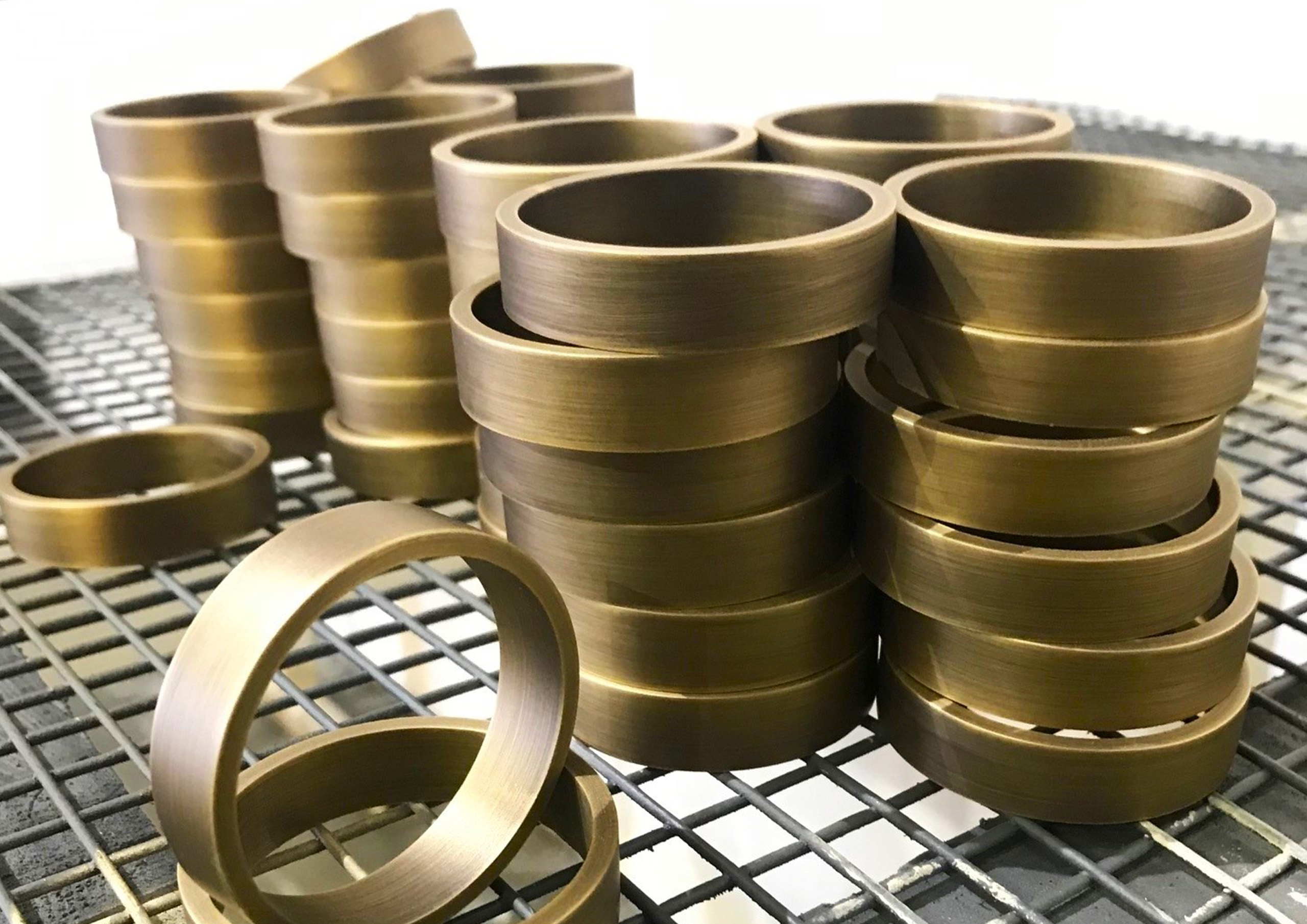

Pre-treatment & Surface Preparation | Powder Coating | Wet Spraying | Specialist Coatings

Maine Surface Finishing is your premier destination for protective coating solutions. Our wide array of services includes chemical and mechanical pre-treatment, epoxy and polyester powder coating, wet painting from C1 to C5M environments and specialised coatings for bespoke customer requirements.

With an unwavering commitment to quality and innovation, we provide durability and aesthetic excellence in all our work.

PRE-TREATMENT & SURFACE PREPARATION

Experienced in all pre-treatments and surface preparations.

WET SPRAYING

Experienced in wet spraying and finishes.

POWDER COATING

Skilled in powder coating applications.

SPECIALIST COATINGS

Experts in specialist coatings.

LABORATORY

Fully equipped labratory for testing and ensuring excellent quality control.